Surface Protection

Surface Protection – Ceramic and Rubber Lining

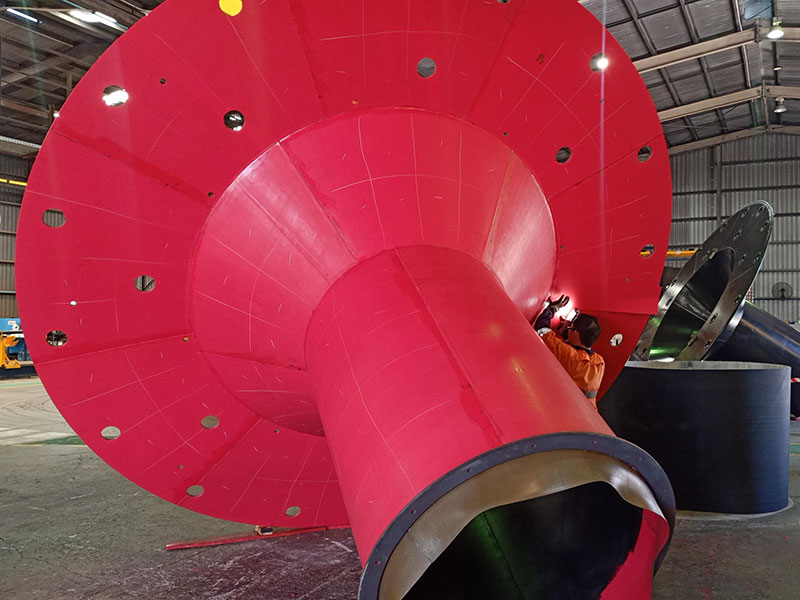

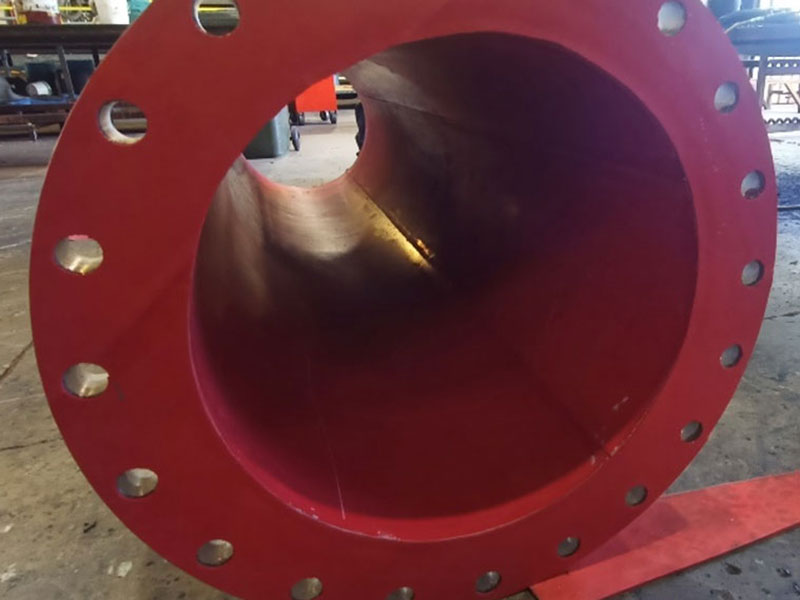

Rubber Lining

Wearmin has decades of experience with surface and wear protection solutions. We have experience with a range of steel sections from chutes to piping to tanks and have the ability to rubber line all surfaces using either a hot vulcanization or cold bonding method.

We have applied a range of rubber types from Natural rubber, Neoprene Rubber, Fire Resistant (FRAS) Neoprene Rubber, Nitrile Rubber, Ethylene Propylene Diene Monomer (EPDM) Rubber, Chlorobutyl Rubber amongst others.

We can include the full scope of supply starting from the fabrication of steel sections, surface blasting preparation, rubber lining throught to the external paint protection with ISO 45001 accreditation principles.

We supply full Quality and Project documentation from NDT, Test certificates, Material certificates, ITP’s, MDR’s and any other Quality requirements you may need.

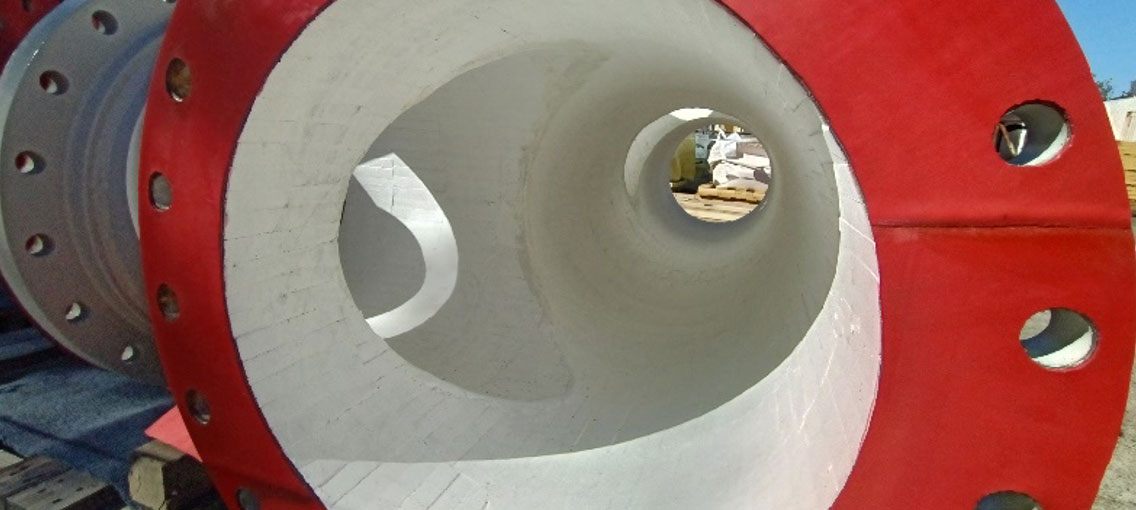

Ceramic Lining

Similar to our Rubber Lining capability, Wearmin has experience with surface and wear protection solutions including ceramic linings. We have experience with a range of steel sections from chutes to piping to tanks and have the ability to ceramic line most surfaces using either ceramic tiling method or ceramic epoxy lining methods.

We have applied a range of ceramics types from Alumina Ceramic tiles to Silica Carbide, rubber backed ceramic panels and other ceramic based epoxy coatings.

We can include the full scope of supply starting from the fabrication of steel sections, surface blasting preparation, ceramic lining through to the external paint protection with ISO 45001 accreditation principles.

We supply full Quality and Project documentation from NDT, Test certificates, Material certificates, ITP’s, MDR’s and any other Quality requirements you may need.